Inventory Management

Real-Time Inventory Visibility

In the fast-paced world of warehousing, having real-time insights into stock levels is invaluable. That’s why ASCTrac provides instant visibility into inventory across multiple locations. This real-time access ensures businesses can track stock movements, anticipate demand, and avoid stockouts or overstocking. By having a clear picture of inventory levels, businesses can make informed decisions, optimize storage space, and reduce holding costs. The ability to access this data in real-time not only streamlines operations but also enhances customer satisfaction as orders can be fulfilled more efficiently.

Automated Reorder Points

Multi-Location Management

Managing inventory across multiple locations can be a challenge. Thankfully, ASCTrac offers a unified view, streamlining stock transfers and providing a holistic view of inventory health. With the rise of e-commerce and global supply chains, businesses often operate in multiple locations. This feature ensures that stock levels are balanced across all locations, optimizing storage space and reducing transportation costs. Furthermore, by having a centralized system, businesses can ensure consistency in inventory records, improving accuracy and reducing discrepancies.

Advanced Reporting and Analytics

In today’s data-driven world, insights into inventory turnover and stock aging are crucial. With this in mind, our system offers in-depth analytics. These insights empower businesses to optimize stock levels, identify slow-moving items, and make informed purchasing decisions. By analyzing sales trends, seasonality, and other factors, businesses can forecast demand more accurately, ensuring they have the right products in the right quantities at the right time. Additionally, with customizable reports, businesses can gain insights tailored to their specific needs, driving continuous improvement.

Lot and Serial Number Tracking

Traceability is paramount in many industries. Recognizing this, our system supports lot and serial number tracking. This feature ensures products can be traced throughout their lifecycle, from production to sale. Whether it’s for regulatory compliance, warranty claims, or quality control, this level of traceability is invaluable. Furthermore, by tracking products at the lot or serial number level, businesses can quickly identify and address any issues, ensuring product quality and enhancing customer satisfaction.

Cycle Counting

Accuracy in inventory records is essential. That’s why our ASCTrac system supports cycle counting. This feature allows for regular verification of stock levels without disruptive full-scale stock takes. By conducting frequent cycle counts, businesses can identify discrepancies early, ensuring accurate inventory records. This not only reduces the risk of stockouts or overstocking but also improves financial reporting. Additionally, by identifying the root causes of discrepancies, businesses can implement corrective actions, reducing errors and improving operational efficiency.

Demand Forecasting

Anticipating future inventory needs is crucial. With our advanced demand forecasting tools, businesses can proactively manage inventory based on predicted demand patterns. By analyzing historical sales data, seasonality, market trends, and other factors, these tools provide accurate forecasts, ensuring businesses have the right products in the right quantities. This proactive approach reduces the risk of stockouts, improves service levels, and reduces holding costs. Furthermore, by aligning inventory levels with demand, businesses can optimize storage space, reduce obsolescence, and improve cash flow.

Integration with Procurement

Seamless operations are the goal of every warehouse. To this end, as inventory levels change, our system triggers procurement processes. This integration ensures timely stock replenishment, reducing the risk of stockouts. By automating the procurement process based on inventory levels, businesses can ensure they always have the right products on hand. This not only improves service levels but also reduces administrative overheads, allowing staff to focus on other crucial tasks.

Customizable SKU Management

Every business has unique inventory needs. Recognizing this, ASC Software allows for customizable SKU definitions. This flexibility caters to specific business requirements, ensuring accurate tracking and reporting. Whether it’s for different product variations, packaging types, or other factors, this customizable approach ensures businesses can manage their inventory effectively. Furthermore, by having a standardized SKU system, businesses can improve accuracy, streamline operations, and enhance reporting.

Customizable Alerts and Notifications

Staying informed is crucial. That’s why our customizable alert system ensures you’re always updated about crucial inventory events. Whether it’s stock level changes, reorder points, or other alerts, this system ensures businesses are always in the loop. By staying informed, businesses can make proactive decisions, optimize stock levels, and enhance service levels.

Returns Management

Efficiently handling returns is vital for customer satisfaction. With this in mind, ASC Software’s ASCTrac system streamlines the returns process. This feature ensures prompt processing and restocking, reducing the administrative burden and improving inventory turnover. By having a standardized returns process, businesses can ensure consistency, reduce errors, and enhance customer satisfaction. Furthermore, by analyzing return data, businesses can identify trends, address quality issues, and improve product offerings.

Perishable Goods Management

Managing perishable goods presents unique challenges. To address this, our system offers tailored functionalities. These features ensure items are managed based on their expiry dates, reducing waste and ensuring product quality. Whether it’s for food products, pharmaceuticals, or other perishable items, this feature is invaluable. By tracking expiry dates, businesses can ensure they sell products in the right order, reducing obsolescence and improving profitability.

Role-Based Access Control

Data security is paramount. That’s why ASCTrac offers role-based access control. This feature ensures that only authorized personnel can access sensitive inventory data. By defining roles and permissions, businesses can ensure data integrity, reduce the risk of errors, and enhance security. Whether it’s for managers, warehouse staff, or other personnel, this customizable approach ensures everyone has access to the data they need, and nothing more.

Integration with Sales and Distribution

Consistency across operations is key. With this in mind, as sales orders are processed, our system adjusts inventory levels automatically. This integration ensures accuracy, reduces the risk of stockouts, and improves service levels. By aligning inventory and sales processes, businesses can ensure they always have the right products on hand, enhancing customer satisfaction and reducing lead times.

Mobile Inventory Management

Efficiency and accuracy are paramount in inventory management. With this in mind, our system integrates seamlessly with mobile, barcode, RF and RFID technologies. These integrations enhance inventory operations, ensuring accurate tracking, streamlined receiving and dispatching, and reduced errors. By leveraging these technologies, businesses can improve productivity, reduce administrative overheads, and enhance customer satisfaction.

Dedicated Support and Continuous Updates

Commitment to excellence is our motto. That’s why, beyond just software, we offer dedicated support and continuous updates. These services ensure businesses always have the best tools at their disposal. Whether it’s new features, bug fixes, or other updates, our team is always on hand to assist. By offering dedicated support, we ensure businesses can maximize the value of their investment, driving continuous improvement and enhancing operational efficiency.

Still have questions? Contact ASC Software today to setup a call or demo Contact Us

Recent Blogs

The Cost of Automated Storage and Retrieval Systems

Reading time: 8 minutes Discover what automated storage and retrieval systems really cost and how they can pay off for your …

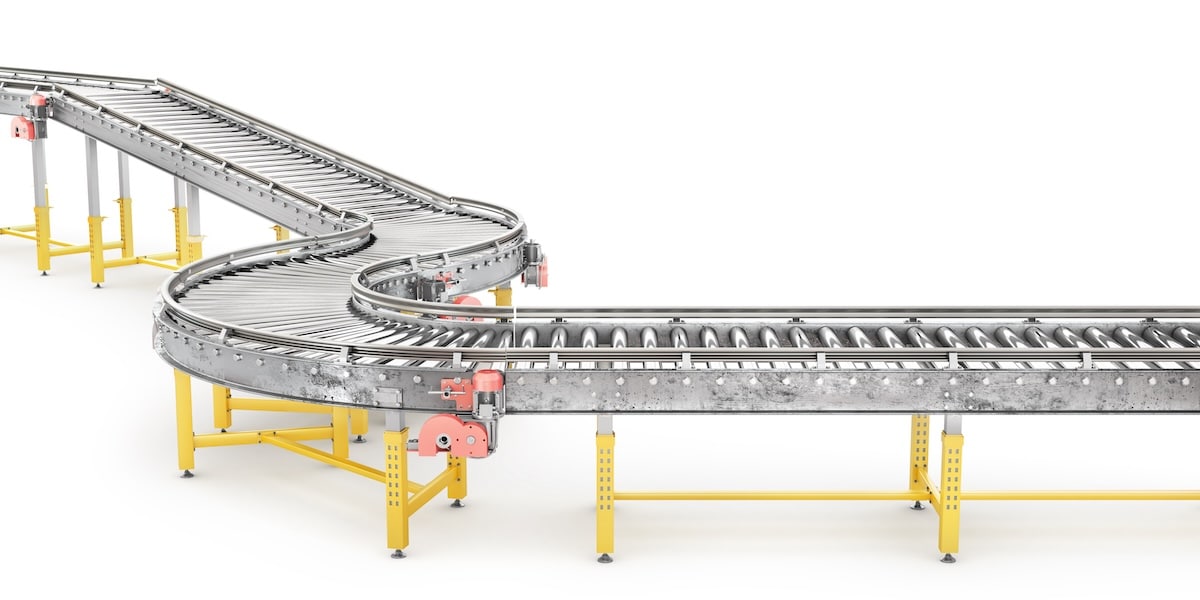

Reading time: 7 minutes Discover how conveyor systems revolutionize warehouse operations, optimizing efficiency and productivity. The Role of Conveyor Systems in …

Maximizing Efficiency with Automated Storage and Retrieval Systems (AS/RS)

Reading time: 9 minutes Learn how Automated Storage and Retrieval Systems (AS/RS) can revolutionize your warehouse operations and maximize efficiency. In …